Ormen Lange Hot Taps

Project: Ormen Lange South Development

Location: Norway North Sea

Client: Statoil AS

Core Service: Project Support

Key Activity: Subsea Hot Tapping

Duration: 18 Months

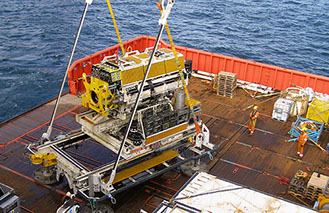

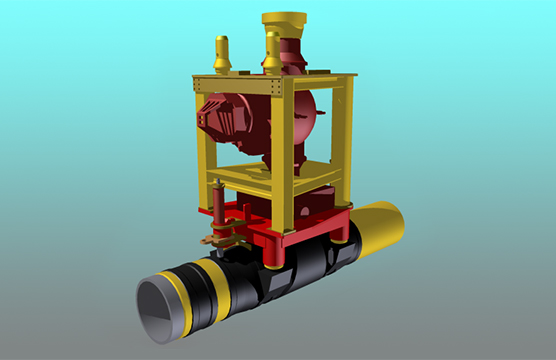

Hot Tap Cutting Module Prior to Subsea Deployment

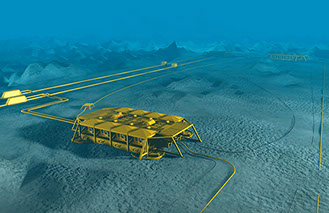

Ormen Lange Hot Tap Arrangement

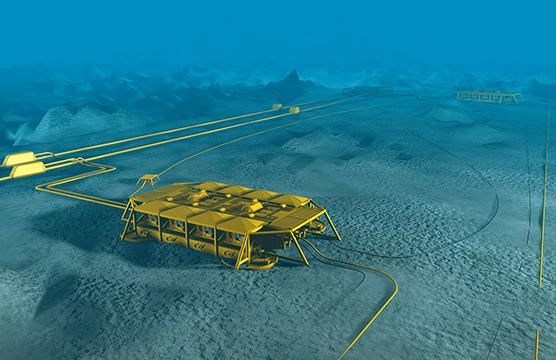

Ormen Lange Valve Module

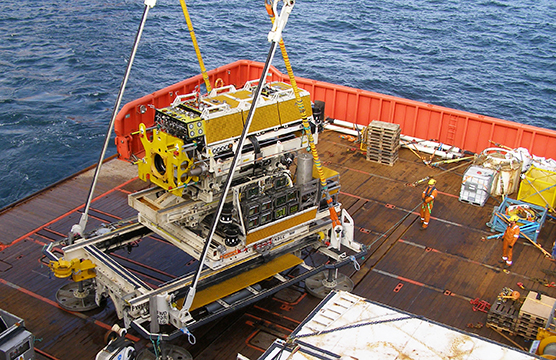

Hot Tap Cutting Module Being Demobilised in Norway (Crew in the pub in the background)

4 - 4

<

>

Project Synopsis:

The Ormen Lange Field is located in 850m of water in the Norwegian sector of the North Sea. The field exports gas to the Nayhamna onshore terminal via two 130km long 30” subsea pipelines. In 2007 the Ormen Lange South Development project awarded a contract to the Statoil PRS team to perform two remote hot taps into the 30” pipelines adjacent to the subsea templates to enable tie-back of the Ormen Lange South Development (OLSD). The hot taps were carried out into two previously installed forged tees which were installed as part of the original pipelines.

CWS Solution and Scope Services:

Statoil required project and operational support for their subsea Hot Tapping Cutting Unit (HTCU), developed by Clear Well in 2005 to support deep water remote hot tapping operations.

The scope of supply included:

advanced High Temperature (HT) seal testing and development of HT seal assemblies, development of flat plate trepan cutters, onshore trials support and offshore operational support.

The two hot tapping operations were successfully completed in August 2009 and constitute the world’s first remote subsea hot taps in addition to the two highest pressure – 255 barg – highest temperature – 95ºC – subsea hot taps completed to date.