Dunbar Replacement Pipeline

Project: Dunbar Replacement Pipeline

Location: UK North Sea

Client: Total

Core Service: Pipeline and Riser Installation

Key Activity: Project Support

Duration: 15 Months

Divers working subsea

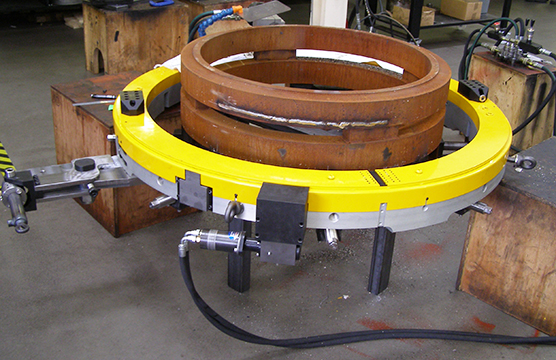

Orbital Weld Removal Tool

2 - 2

<

>

Project Synopsis:

The Dunbar coaxial pipeline conveys multiphase production fluids from the Dunbar platform to the Alwyn platform. In 2006, intelligent pigging detected internal corrosion within the pipeline and the Dunbar Replacement Pipeline project was launched to effect a replacement within 12 months.

The new pipeline and two replacement risers were designed, installed and commissioned within 15 months to the credit of all parties involved.

CWS Solution and Scope Services:

The CWS scope included the provision of package leaders for the three core works; design, fabrication and installation of an insulated pipe in pipe pipeline, design and fabrication of the two replacement risers and commissioning of the platform works and the finished pipelines and risers. In addition, two specialist machine tools were designed and manufactured to facilitate removal of seam welds and anode doubler plates from the platform structural members.

The CWS scope included:

preparation of the Pipeline Works Authorisation (PWA) and Major Accident Prevention Documents (MAPD), review of riser designs, provision of lead engineers for all major offshore and remote site activities, design and manufacture of the Seam Weld Removal Tool (SWRT) and Orbital Weld Removal Tool (OWRT) and ad hoc engineering support throughout the project.